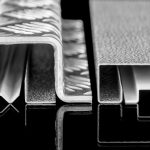

We perform bending of ferrous and non-ferrous sheet metal on a DURMA CNC power brake

Materials for bending – galvanised steel (DX51+Z), steel (S235, S355), stainless steel, aluminium, copper.

We can also perform surface finishing of bent profiles (galvanising, anodising, bluing, powder coating, etc.).

Basic technical parameters:

- 4 controlled axes

- maximum length of bent profile: 3050 mm

- bending angle: 10 – 90°

- bent material thickness: 0.5 – 5 mm

Applications:

- Advertisements (illuminated panels, brackets…)

- Civil engineering (metal plating, replacement of load-bearing structures, supporting profiles…)

- Engineering (housings for machinery…)

Shape Cutting

Burnouts are produced using a laser and are most commonly made from sheet steel. We can also perform other operations on the burnouts, including threading, countersinking and deburring.

Materials: Steel (S355, S235 and others), stainless steel or aluminium

Our burnouts are produced using CNC laser cutting machine TRUMPF 3030

Basic technical parameters:

- Maximum sheet dimensions: 1 500 x 3 000 mm

- Maximum sheet thickness: Fe = 20 mm, stainless steel = 12 mm, Al = 8 mm